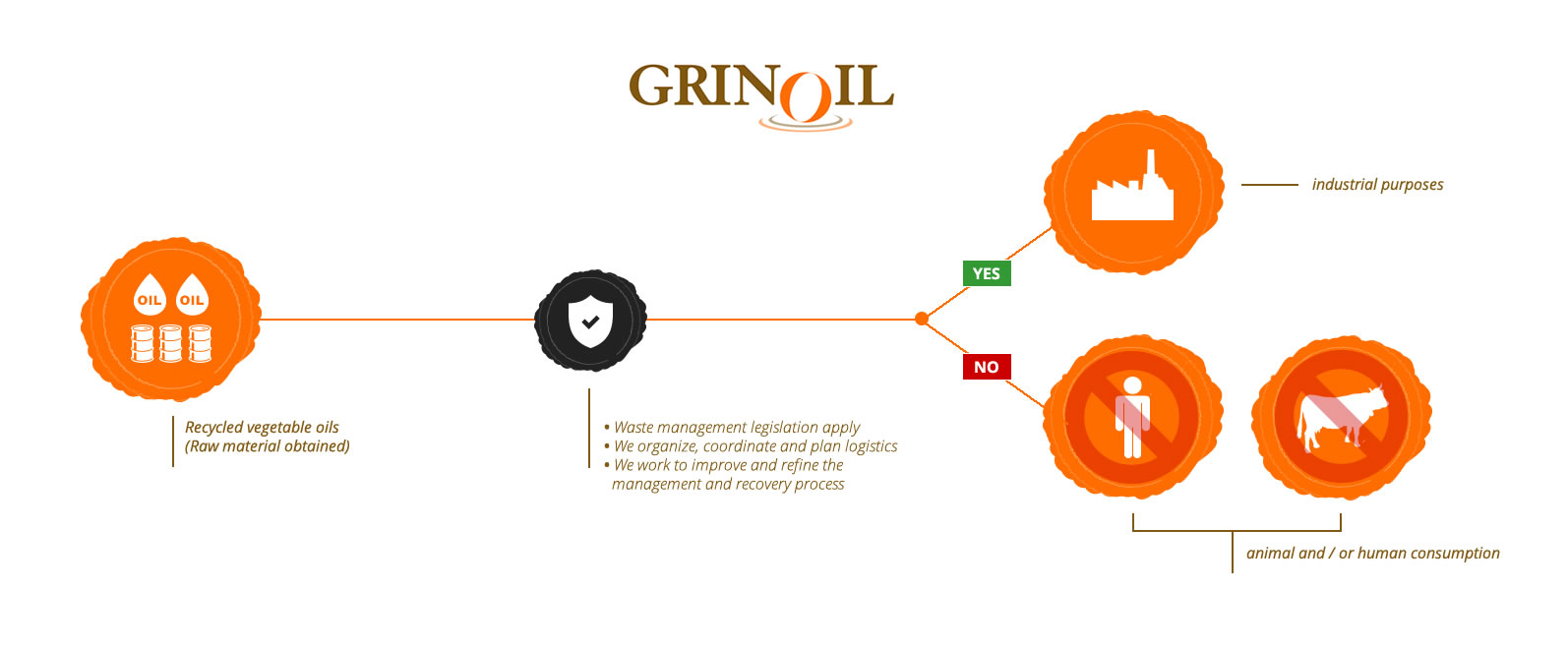

Production and commercialization of used fats and oils

In order to conduct our activity, we have established a process that is organized into different phases:

Process in the plant

Reception, control and analysis: when the waste is received in our management plant, it is weighed, loading is monitored and a sample is taken. The sample is analysed in our laboratory to identify the specifications of the fats and oils in terms of its qualities, mainly in terms of humidity and impurities, oleic acid, iodine and sulphur content, and regular monitoring of the composition of the fatty acids using chromotography. Once the analysis has been completed, it is approved for unloading and input to the recovery process. We are able to accept oil in any format or container, from small volume bottles and tanks, drums with capacities of 30, 50, 60, 120, 200 and 1000 kg, right up to tankers.

Reception, control and analysis: when the waste is received in our management plant, it is weighed, loading is monitored and a sample is taken. The sample is analysed in our laboratory to identify the specifications of the fats and oils in terms of its qualities, mainly in terms of humidity and impurities, oleic acid, iodine and sulphur content, and regular monitoring of the composition of the fatty acids using chromotography. Once the analysis has been completed, it is approved for unloading and input to the recovery process. We are able to accept oil in any format or container, from small volume bottles and tanks, drums with capacities of 30, 50, 60, 120, 200 and 1000 kg, right up to tankers.- Unloading and first filtration: the waste is unloaded using a decanting hopper, enabling the first filtration in which the solid remains of organic matter in the oil are separated.

- Transfer to settling tank and second filtration: the oils are transferred from the hopper to the first production tank using a centrifuge pump fitted with a filter to filter finer sediment in the second filtration.

- Settling and sanitization: once the oil is in the tank, it is left to settle and heat is applied to reach a homogeneous temperature of around 60ºC, enabling us to settle the waste in order to separate the rest of the solid particles and water from the oil.

- Draining and second settling: after the optimal settling time, the tank is drained, with the oil being separated from the solid fraction and the water. This fraction is deposited in the tank assigned for such waste and the oil is transferred to the final tank where it is subjected to a second much shorter settling process. The used vegetable oil can now be considered a recovered product or, in other words, a useful raw material.

Final loading and analysis: the recovered used vegetable oils are loaded on to a tanker, going through the final filtration using the centrifuge pump. The loaded product is sampled and analysed to verify that it complies with the specifications and quality indicated and requested by our customers. The product is then transported directly to the end customer.

Final loading and analysis: the recovered used vegetable oils are loaded on to a tanker, going through the final filtration using the centrifuge pump. The loaded product is sampled and analysed to verify that it complies with the specifications and quality indicated and requested by our customers. The product is then transported directly to the end customer.

Commercialization

We directly manage the sale of the recovered used vegetable oils through our sales department.

Other information

- The raw material obtained (recovered used vegetable oils) are used solely and exclusively for industrial processes and never for animal or human foodstuffs.

- Throughout the process, we comply fully with current legislation on waste management.

- We organize, coordinate and plan all aspects of logistics at all stages of the process, both in terms of the needs of the producer and the end customer.

- Grinoil ensures that it works every day to improve and perfect the management and recovery process, studying and applying all of the possible improvements both in terms of the human team and technical aspects.